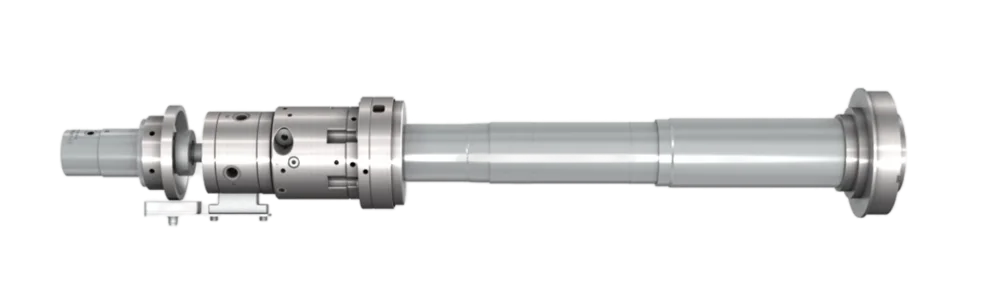

Spindle assemblies

Customized actuators, sensors and media distribution.

- Individually designed

- Optimally adapted to difficult process parameters

- Compact design

- Precisely manufactured

Spindle assemblies describe actuation units of clamping systems. They also supply additionally required media such as hydraulics, pneumatics or coolant.

Our spindle assemblies usually consist of clamping cylinders, rotary distributors, tie rods with media feed-through and sensors.

The individual design is always optimally adapted to the requirements of the clamping system, the machine spindle and the machining process. In this way, they create the basis for optimum, μ-precise workpiece machining.

With run-outs < 0.05 mm on the back of the spindle, our tension connections, clamping cylinders and media distributions reduce vibration and temperature influences on the machine spindle and the process.

For customized high-end production technology.

Actuation unit for clamping systems with media feed-through. Design always optimally adapted to the requirements of the clamping system and the machining process.

Actuation unit for clamping systems with media feed-through. Design always optimally adapted to the requirements of the clamping system and the machining process.

Actuation unit for clamping systems with media feed-through. Design always optimally adapted to the requirements of the clamping system and the machining process.

Mechatronic actuation unit with feed-through of energy and media for actuation and real-time-capable data and signal transmission to and from the associated clamping system.

Combined actuating unit for clamping systems with integrated single-piston clamping cylinder and additional movable and detachable sleeve.

Highest quality thanks to strict controls.

We offer you reliable quality, as our clamping systems undergo two tests during manufacture and before delivery:

- Measurement of each relevant individual part before assembly: checking dimensional accuracy, shape and position tolerances.

- Extensive endurance tests on our test bench after assembly.

“We inventors from the Black Forest have always had a high technological influence on progress within many industries – worldwide. Our high level of specialization is a guarantee for both technical challenges and sustainable business – and therefore future security.”

Johannes Sterman, Managing Director

Everything from a single partner.

For new machines as well as for conversion projects: We accompany you from the first idea and the initial technical concept through design, production and project management to commissioning and far beyond.