Devices & mechanical engineering

Innovative production technology for your workpieces.

- Individually integrated into the production layout

- Maximum dynamic and positioning accuracy < 0.05 mm

- Smart and compact design

- Condition monitored

- Industry 4.0 ready and networked

At the heart of our fixtures and machines are µ-precise clamping systems.

We create flexible fixtures around the clamping system and can take care of the entire mechanical engineering on request.

As a system supplier, we take responsibility for the entire project and implement high-precision, smart and CE-compliant production systems.

μ-THINKING®- for customized high-end production technology.

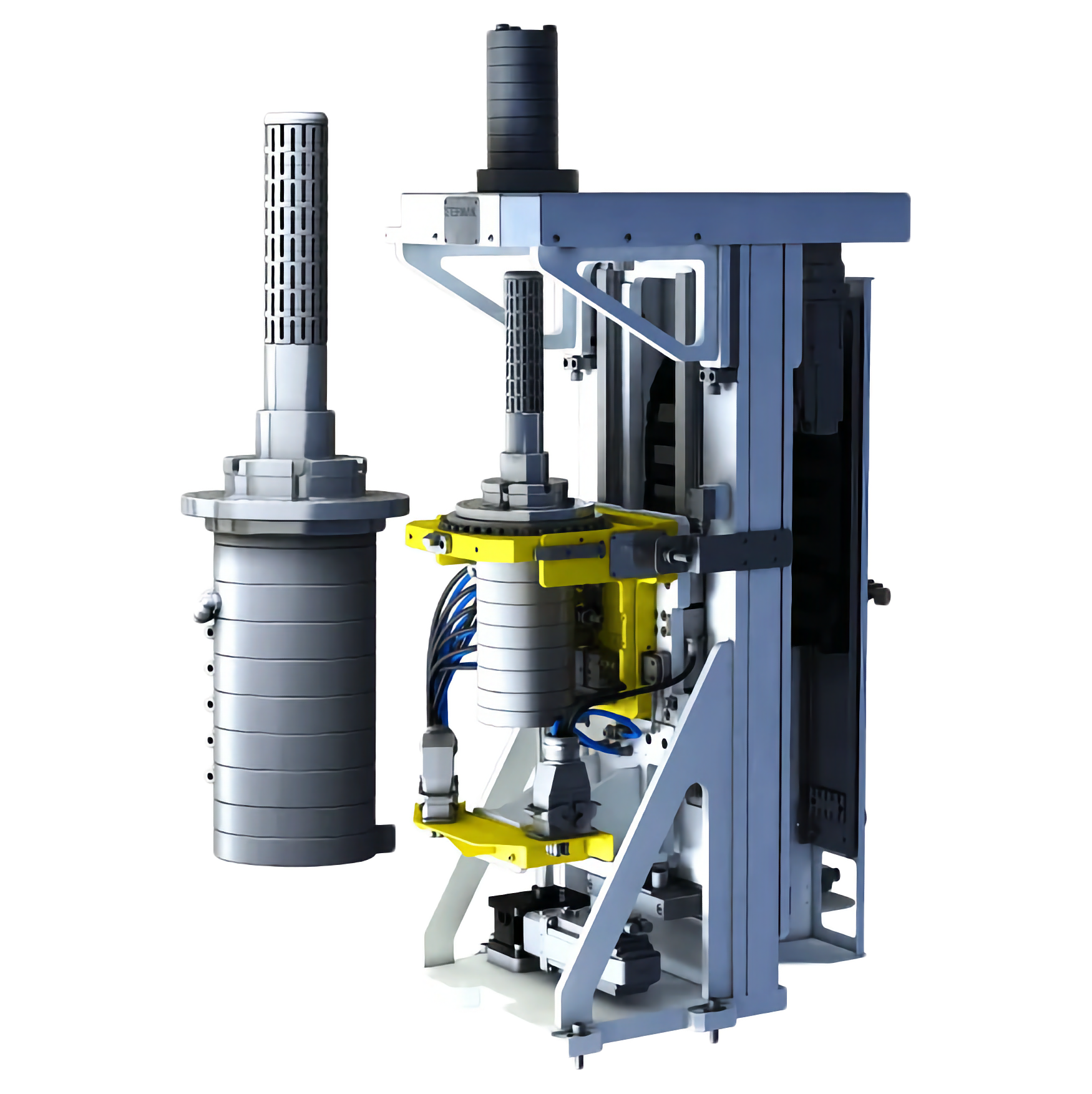

Here as a centre drive system in an extra compact design for use in grinding; for machining shafts or turbine blades.

Shown here as a centre drive system in a short version for machining shafts.

Shown here as a centre drive system in a medium-length version for machining shafts.

Shown here as a centre drive system in a long version (heavy-duty) for machining shafts.

Here as an implementable complete system for assembling and joining stator packs with up to 8 separately controllable clamping levels.

Here as a system for centring and clamping housings in a mill-turn machine. With optimised clamping design and balancing quality for low-deformation and centrifugal force-neutral machining.

Here as a system for holding and clamping planer knives. Designed with a swivelling axis and two separately controllable clamping levels with six compensating plane clamping elements.

Highest quality thanks to strict controls.

We offer you high-end quality because our systems undergo two tests during manufacture and before delivery:

- Measurement of each relevant individual part before assembly: checking dimensional accuracy, shape and position tolerances.

- Extensive endurance tests on our test bench after assembly.

“We inventors from the Black Forest have always had a high technological influence on progress within many industries – worldwide. Our high level of specialization is a guarantee for both technical challenges and sustainable business – and therefore future security.”

Johannes Sterman, Managing Director

Everything from a single partner.

For new machines as well as for conversion projects: We accompany you from the first idea and the initial technical concept through design, production and project management to commissioning and far beyond.