Concept, development & design

Concept

Development & Design

Production & assembly

Quality control

Lifecycle

Service & Retooling

Our μ-THINKING® makes the difference for you. Right from the start.

For us, μ-THINKING® means the perfection of details and a consistent focus on the individual requirements of our customers. The smallest mechanical unit is a μ our benchmark. With μ-THINKING®, we further develop clamping systems and processes, network them digitally and make them more economical, precise and future-proof – for production technology that is high-quality and efficient. We consistently align our engineering with this basic conviction, from the initial idea to conception and development.

Concept

We develop customized clamping concepts.

We only need a little at the start of each clamping task: Based on your workpiece drawing and machining information for each planned operation, we develop a tailor-made clamping concept. An STP model of the workpiece to be machined is also helpful for detailed analyses and simulations. If a specification or requirements specification is already available, we integrate these specifications directly into the concept development. Our concept presentation – if necessary also with possible alternatives and associated offer – provides you with a sound basis for decision-making.

- Flexible design of the clamping system for one or more similar workpieces via clamping sets

- Adaptation of the interfering contours to your machine room and your tool turret

-

Optimum design of the clamping and centering for your individual workpiece

-

Direct contact and support throughout the entire life cycle

-

Integrated central lubrication or lubricated sealing air as required and available for low wear

-

Customized design for your spindle nose

-

Weight-optimized for no imbalance influences

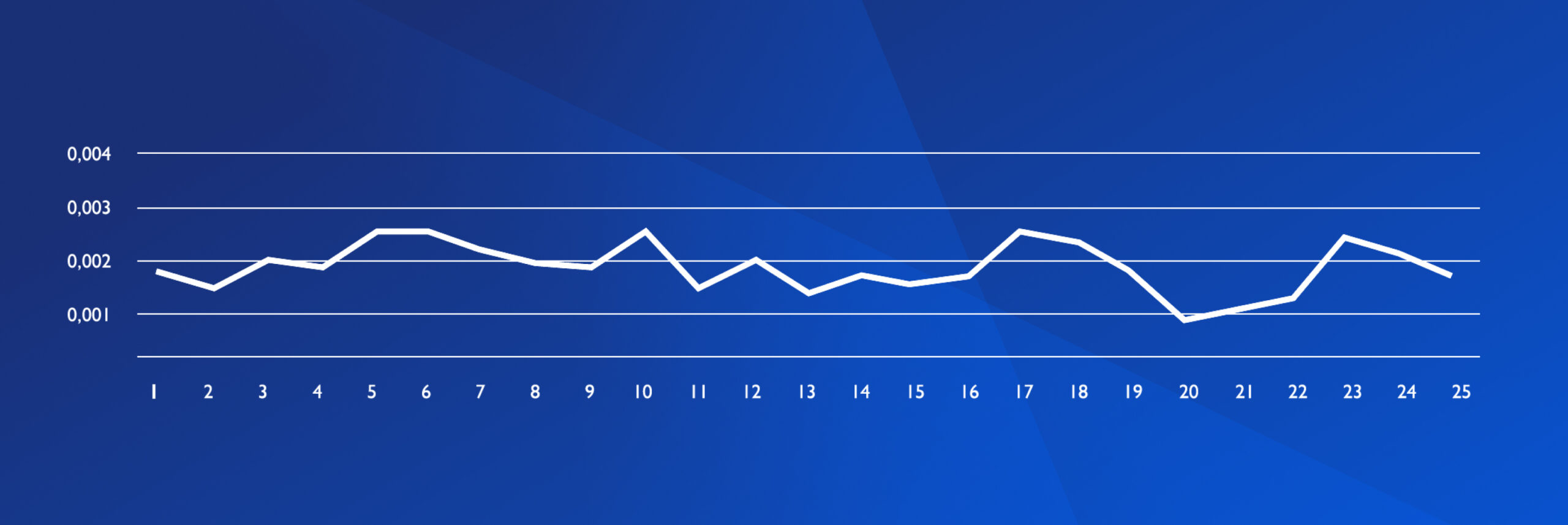

Roundness in millimeters: Hard turning of the bore of a helical gear wheel, reference Ø 85 mm.

Design & Development

We combine new ideas with years of experience.

We start our design and development work open to technology and exactly according to your specifications: in this way, innovative ideas can unfold their full potential – free from the restrictions of pigeonholing or modular principles.

In the project kick-off, sales and development engineers discuss the concept approaches developed in accordance with the dual control principle. Only then does the CAD design work begin.

We incorporate our decades of technological experience from numerous successful projects into every new development.

During the iterative development process, we stay in close contact with you – from milestones reached to the final release meeting after we hand over your project to our production department.

Find out here how we produce high-quality products: