Production, assembly & quality control

Concept

Development & Design

Production & assembly

Quality control

Lifecycle

Service & Retooling

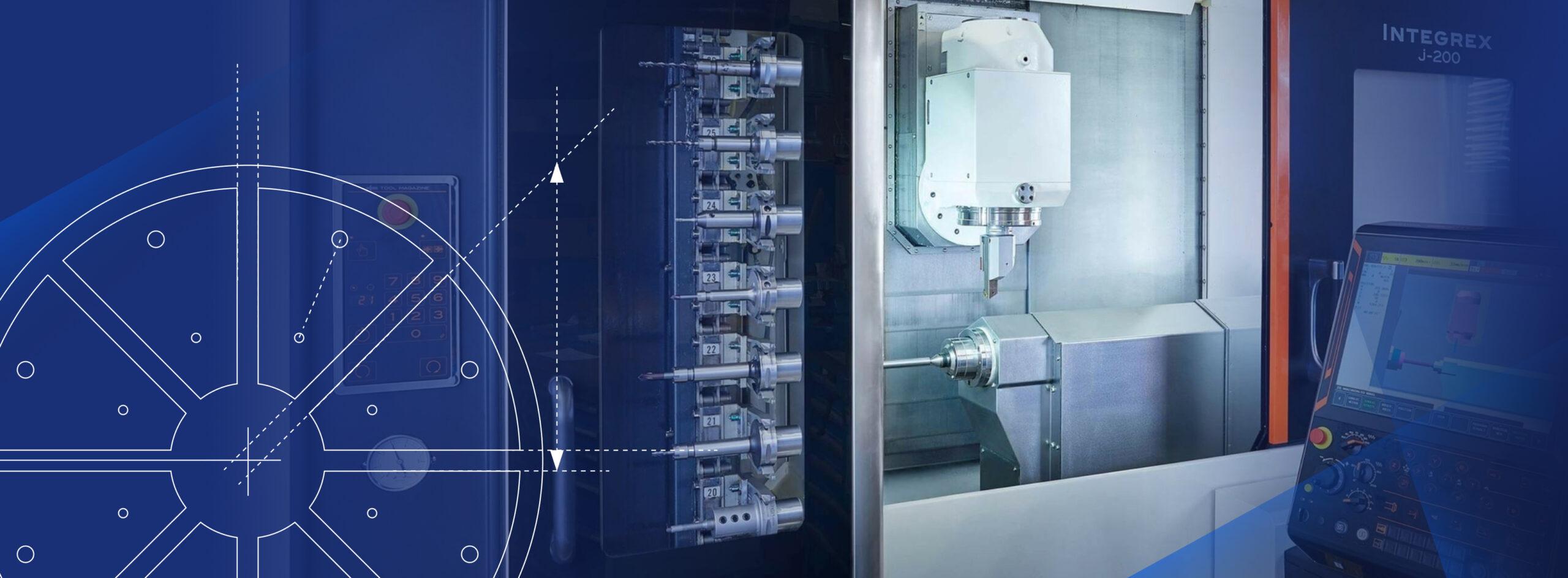

State-of-the-art turning, milling, grinding, assembly and targeted testing processes.

We provide our customers with comprehensive support from the initial concept through to machining production and throughout the life cycle of the clamping system. We manufacture all key components ourselves and have high-end machinery for state-of-the-art manufacturing processes. Our customers can rely on us throughout the entire product life cycle – as well as on our manufacturing solutions.

With a vertical integration of over 85%, we manufacture key assemblies here in the Black Forest. Our development engineers and production specialists exchange information intensively during production. We have developed our own digital process specifically for this purpose.

In this way, incremental ideas for individual parts also flow directly into your clamping technology solution.

Production

We stand for precision - made in the Black Forest.

With our state-of-the-art machinery, we cover all important core processes such as CNC turning, CNC milling and CNC grinding as well as comprehensive quality control including final assembly.

We rely on the expertise of long-standing, regional partners for heat treatment and the various finishing steps.

CNC turning:

- MAZAK QuickTurn SMART

- MAZAK QuickTurn NEXUS 2

- MAZAK Integrex i-200ST SMART

- MAZAK Integrex j-200

- MAZAK Integrex i-200

- CORE

- Tools: TopSold & Smooth, STS Indoor Tracking of all projects

CNC milling:

- HERMLE C 42u

- HERMLE C 32u + RS1

- DMU 80p DuoBlock

- DMU 80p MonoBlock

- DMU 80p

- DMU 50evo linear

- DMU 40evo linear

- Tools: SolidCam & DBWorks, STS Indoor Tracking

CNC grinding

- WEMA S6

- VOUMARD 1000

- KELLENBERGER 100

- KELLENBERGER Varia 175

- 2 x KELLENBERGER UR 1500

- 2 x KELLENBERGER UR 1000

- Tools: STS Indoor Tracking

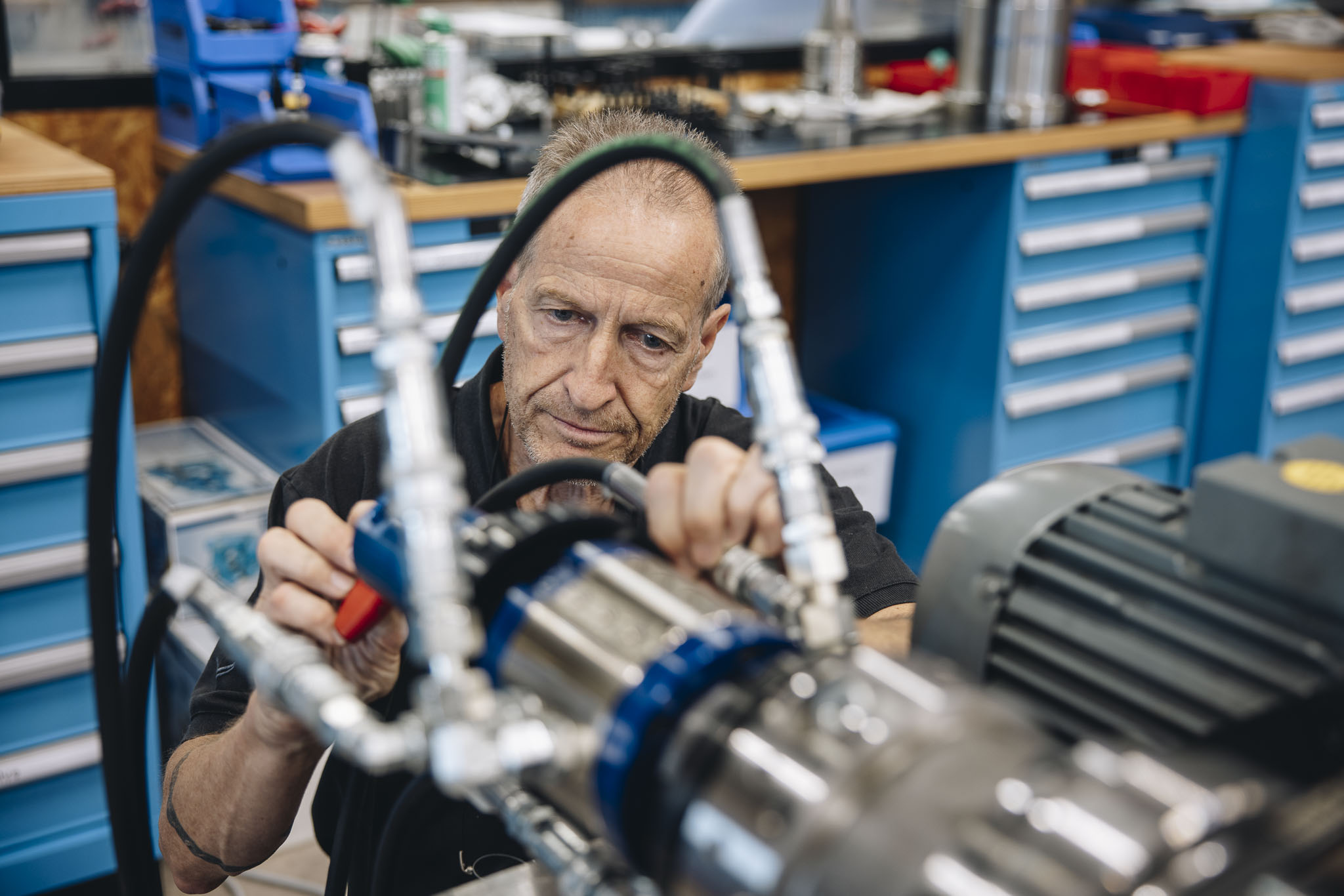

Assembly

We deliver the highest quality every step of the way.

Assembly determines the quality of the entire system – and therefore productivity. Production can only run smoothly if every system component and every assembly is manufactured and installed with precision.

We take every step carefully – from pre-acceptance to incoming goods to outgoing goods, final inspection and the use of state-of-the-art tools such as SolidCam, DBWorks or STS Indoor Tracking.

Quality control

WE OFFER YOU SECURITY.

Before assembly begins, all final individual parts undergo a 100% inspection in our measuring room. Dimensions, shape and layers in the μ-range are checked here.

After initial assembly, we subject the finished systems to additional static and dynamic test runs on our test bench – using your original workpieces.

For quality control, we use LEITZ PMM 8666 and tools such as QUINDOS and STS Indoor Tracking.

Find out here how we ensure quality and enable flexibility: